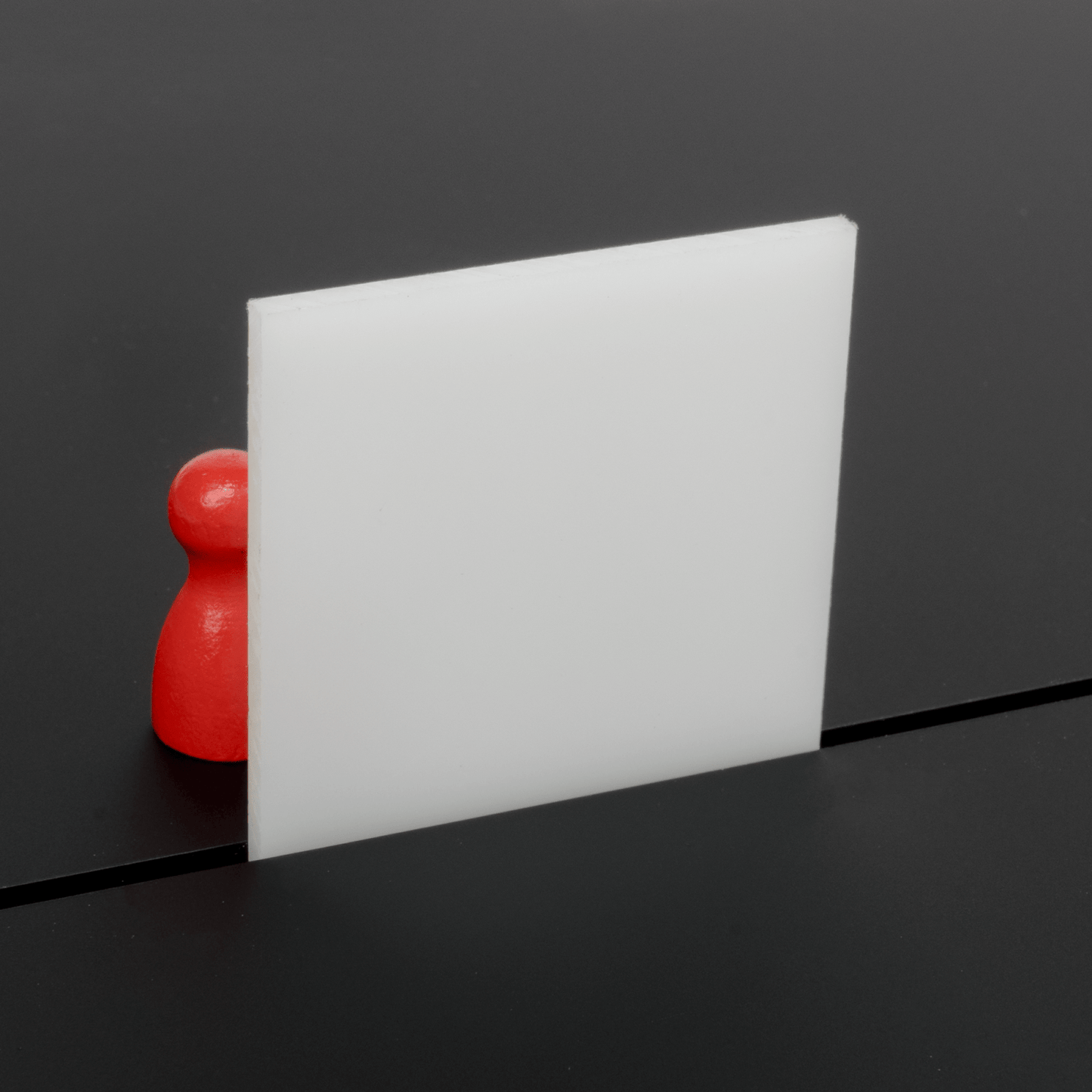

Material Overview

Polyacetal (also known as Delrin or POM) is a high-quality engineering thermoplastic with excellent mechanical properties. It combines high strength and stiffness with low friction and very good dimensional stability. Thanks to its wear resistance, chemical resistance, and temperature resistance, it is widely used as a metal replacement in technical components. Ideal for laser cutting and engraving where precision and durability are key.

✔ Highlights

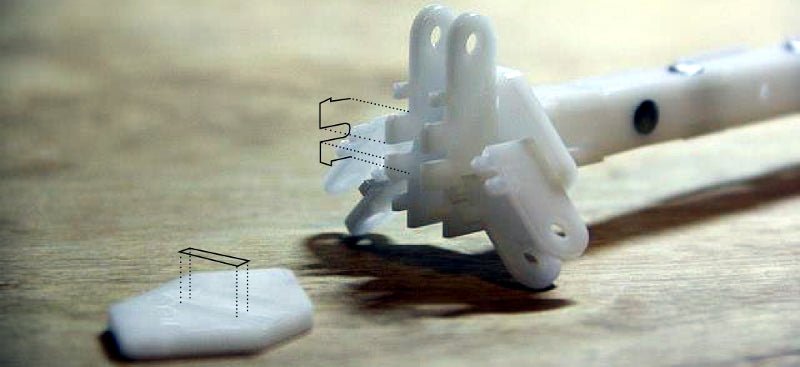

✔ Laser compatible – clean cuts and neat engravings

✔ High mechanical strength and wear resistance

✔ Low friction and excellent dimensional stability

✔ Resistant to chemicals and moisture

✔ Temperature resistant from -40 °C to +120 °C

✔ Highly suitable for technical and mechanical applications

For which laser source is this material suitable?

✅ Geschikt voor CO₂ lasers

❌ Niet geschikt voor diodelasers

Applications

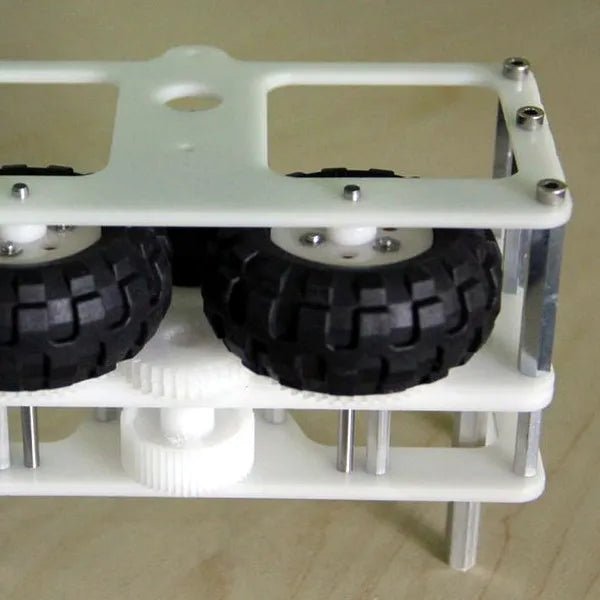

For hobbyists:

Ideal for robotics, model building, and mechanical designs such as gears, hinges, and moving parts that require precision.

For professionals:

Widely used in automotive, mechanical engineering, and electrical engineering for bearings, housings, gears, connectors, and other precision components that demand high reliability.

Technical Specifications

Material Type: Polyoxymethylene (POM / Delrin)

Finish: Smooth surface, technical appearance

Density: ± 1.4 g/cm³

Thickness Tolerance: < 10%

UV Resistance: Limited – not suitable for prolonged outdoor use

Cutting Width: ± 0.2 mm

Minimum Cutting Shape: approx. 6 × 6 mm

Minimum Engraving Detail: approx. 1 mm

Machinability: Excellent for laser cutting, milling, and CNC machining; high dimensional stability with temperature variations

Are you looking for a technical precision material that is laser-friendly and robust?

Polyacetal (POM / Delrin) combines strength, precision, and workability – ready for your laser projects.